Werkzeug-Lager- und Entnahmesystem

Macrodyne liefert Matrizenlager- und Entnahmesysteme für Matrizen oder Matrizensätze von mehreren hundert Pfund bis 100 Tonnen oder mehr. Unsere Werkzeughandling-Ausrüstung wird speziell für Ihre Anwendung entwickelt und kann eine oder mehrere Pressen in einer Vielzahl von Konfigurationen bedienen.

Macrodyne Werkzeug- und Werkzeughandlinggeräte in Verbindung mit Werkzeugschnellwechsel-Spannsystemen verbessern die Effizienz und Produktivität von Pressen oder Pressenlinien durch Minimierung der Stillstandzeiten, die während des Werkzeugwechsels auftreten. Dies gilt insbesondere im Hinblick auf die Anforderungen von Just-in-Time oder Kleinserien.

Unser automatisiertes Werkzeuglagerungs- und -bereitstellungssystem umfasst ein umfassendes Werkzeug- und Werkzeugmanagement, komplett mit Werkzeug- und Werkzeugerkennung, Registern, flexibler Lagerung, Vorbereitstellungsfähigkeit, Fehlerdiagnose, Integration mit Pressen oder Pressenlinienmonitoren sowie System- und Werkzeugstandortüberwachung.

Macrodyne bietet eine große Auswahl an Werkzeug- und Formenhandhabungsgeräten für praktisch jeden Vorgang und jeden Automatisierungsgrad. Die Werkzeuge oder Formen können mit Brückenkränen, Gabelstaplern aus den Systemen ausgetauscht oder auf Regalen gelagert und automatisch ausgelagert werden, wie dies bei automatisierten Werkzeug-Ein- und Auslagerungssystemen möglich ist. Egal, ob Sie eine mechanische, servo- oder hydraulische Presse haben, Macrodyne bietet die richtige Lösung für Sie.

Macrodyne liefert eine breite Palette von Werkzeug- und Formenhandhabungsgeräten, darunter:

- Automatisierte Werkzeuglager- und Bereitstellungssysteme

- Automatisierte Werkzeug- oder Werkzeugspann- und Hebepakete

- Einzel- oder bidirektionale Werkzeug- und Formenwagen

- AGV (Automatic Guided Vehicle)

- LGV (Laser Guided Vehicle)

- RGV (Schienengeführtes Fahrzeug)

- Matrizen- und Formentupferpressen

- Rollbacken

- Werkzeug- und Formentransfertische

- Werkzeug- und Formenöffner

- Werkzeug- und Formenaufzüge

- Werkzeug- und Formenlagerregale

- Werkzeug- und Formenträgerplatten

- Die Splitter

Werkzeughandling-Ausrüstung für bestehende oder neue mechanische und hydraulische Pressen

Die Matrizen- und Formenhandhabungsausrüstung von Macrodyne kann kundenspezifisch entwickelt werden, um sie in vorhandene mechanische und hydraulische Pressen zu integrieren, oder als Zusatzausrüstung als Teil einer automatisierten Pressenlinie mit neuen hydraulischen Macrodyne-Pressen geliefert werden.

Macrodyne Werkzeug- und Formenhandhabungssysteme sind mit umfassenden elektrischen Steuerungspaketen ausgestattet, die eine einfache, flexible und benutzerfreundliche Funktionalität bieten, die zu einer schnellen und sicheren Handhabung von Werkzeugen und Formen führt.

Formen schnell und sicher wechseln, lagern und abrufen

Ein weiterer großer Vorteil der Werkzeug- und Formenhandhabungsgeräte von Macrodyne ist die Möglichkeit, große Werkzeuge zum Be- und Entladen schnell und sicher zur und von der Presse oder Pressenlinie zu transportieren.

Schwerlastregalsysteme sind verfügbar, um mehrere bis Hunderte von Werkzeugen sicher zu lagern. Diese Regalsysteme sind als eigenständige Artikel erhältlich oder können in Verbindung mit anderen automatisierten Werkzeug- und Formenhandhabungsgeräten geliefert werden.

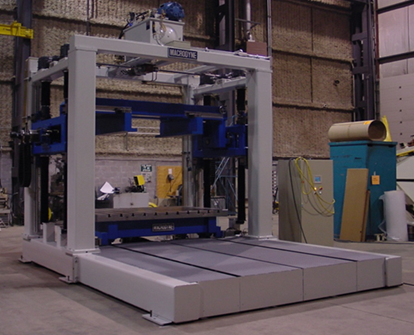

Das obige automatische Matrizenlager- und -entnahmesystem von Macrodyne wurde entwickelt, um vierzig (40) Matrizen mit einem maximalen Gewicht von 20.000 lbs automatisch zu lagern, zu entnehmen und zu handhaben. Dieses System wurde geliefert, um zwei (2) mechanische Pressen zu bedienen, die bereits beim Käufer installiert waren. Das Werkzeuglager- und Bereitstellungssystem besteht aus einem mehrstöckigen Werkzeugwagen mit integriertem Hubtisch inklusive Werkzeuglade-/Entlademechanismus, sieben (7) Werkzeuglagerregalen mit jeweils sechs (6) Stationen und zwei (2) Werkzeugtransfertischen. Das Steuerungssystem speichert Positionsinformationen für jedes Werkzeug im System und die Bereitstellungspositionen ermöglichen das Be- und Entladen der Pressen in fünf (5) Minuten.

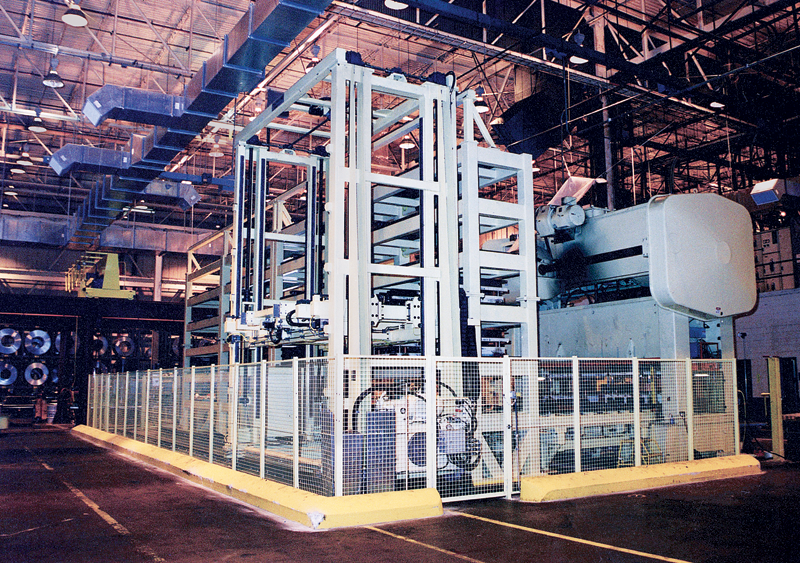

Die obige hydraulische Tandempressenlinie von Macrodyne wurde komplett mit einem vollständig integrierten automatischen Macrodyne-Werkzeuglager- und -bereitstellungssystem geliefert. Neben der Produktion eines neuen Teils alle 6,5 Sekunden ist das System in der Lage, einen kompletten Linienwechsel (alle Werkzeuge und Transfersystemwerkzeuge) in weniger als 10 Minuten durchzuführen. Das Werkzeug-Lager- und Entnahmesystem tauscht automatisch und schnell vier (4) 27.000 lb. stirbt aus vier (4) Pressen. Das Werkzeuglager- und Auslagerungssystem besteht aus vier (4) ebenen Werkzeugaufzügen und vier (4) ebenen Werkzeuglagerregalen mit zwanzig (20) Lagerplätzen und acht (8) zusätzlichen Werkzeugwechselpositionen für die Vorbereitstellung.

Rollbacken & Shuttles

Optionale Rollbacken erleichtern den schnellen Werkzeugwechsel per Gabelstapler oder Laufkran

Hydraulische Pressen von Macrodyne sind mit einer Vielzahl von optionalen Rolltischen oder Werkzeugwechseltischen erhältlich, die es ermöglichen, das Werkzeug zum vereinfachten Transport mit einem schweren Gabelstapler oder Brückenkran aus der Presse zu transportieren.

Unsere Rolltische sind mit automatischen Spannpaketen für die obere Werkzeughälfte kombiniert und in die Pressensteuerung integriert, um eine schnelle und sichere Entnahme des Werkzeugs oder der Form aus der Presse zu ermöglichen.

Mit einem einzigen Rolltisch kann ein kompletter Werkzeugwechsel innerhalb von ca. 15 Minuten durchgeführt werden, sofern sich das nächste zu verwendende Werkzeug in der Nähe der Presse befindet.

Neben der Zeitersparnis wird das Risiko von Schäden an Werkzeugen und anderen Geräten durch menschliches Versagen beim Werkzeugwechsel eliminiert.

Schnellerer Werkzeugwechsel durch duale Rollbacken- Anordnungen

Um Ausfallzeiten im Zusammenhang mit Werkzeugwechseln weiter zu reduzieren, bieten wir zwei Rollbackenpakete an. Bei einer Doppelrolltischkonfiguration kann das nächste in der Presse zu verwendende Werkzeug auf dem zweiten Rolltisch vorbereitet werden, während die Presse noch in Betrieb ist. Wenn ein Werkzeugwechsel bereit ist, verlässt der Tisch in der Presse, und sobald er frei ist, kann der zweite Tisch in die Presse eintreten, was einen Werkzeugwechsel in weniger als 5 Minuten ermöglicht.

Benutzerfreundliche Steuerungen vereinfachen den schnellen Werkzeugwechsel. Um ein Werkzeug aus einer Presse mit Rolltisch zu entnehmen, wählt der Bediener einfach die entsprechende Operation in der Pressensteuerung aus und das Oberwerkzeug wird automatisch vom Stößel gelöst.

Nach dem Trennen vom Schlitten fährt der Bolster aus der Presse in eine sichere Position, wo er mit einem Laufkran entnommen werden kann. Anschließend kann ein neues Werkzeug auf den Rolltisch abgesenkt werden und der Vorgang wird automatisch in umgekehrter Reihenfolge wiederholt, um das neue Werkzeug in die Presse einzubauen.

Macrodyne Rolltische und Werkzeugwechseltische sind in verschiedenen Konfigurationen erhältlich:

- Rollbacken von vorne nach hinten, die aus der Vorder- oder Rückseite der Presse herausfahren

- Von beiden Seiten der Presse ausfahrende seitliche Rollbacken

- Rollbacken vom Typ „T“, die aus jeder Seite(n) der Presse herausfahren

- Einzel- oder Doppelwerkzeug-Shuttles, die mit jeder Seite(n) der Presse verbunden sind